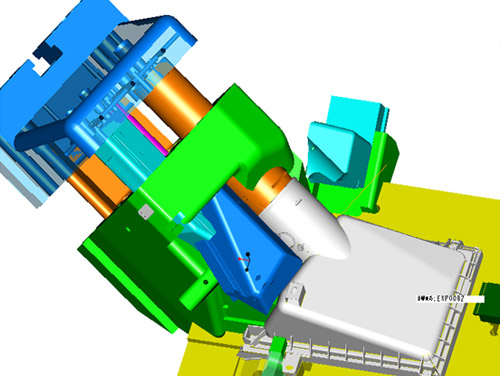

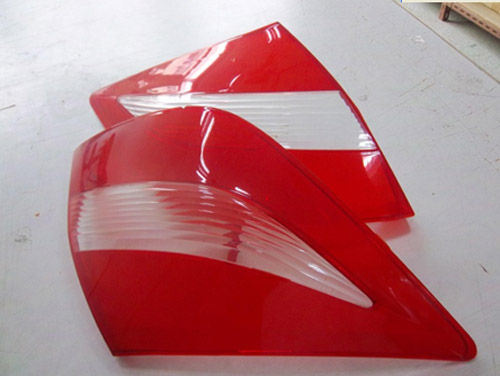

We attach great importance to design, a mold project success or failure depends on the design of the beginning! Correct injection mold design is crucial to having a profitable business. A proper design will ensure quality plastic parts will be produced for the intended life of the mould at the expected cycle time.

Our design department leverages its extensive knowledge to develop high Quality injection molds and close tolerance parts. They achieve this by using a variety of CAD programs that streamline the process and provide innovative and practical solutions. Our experience ranges from large complex molds that produce millions of parts per year to small prototype molds with low production requirements. The importance of cycle time, mechanical movement and mold maintenance goes into every design we create.

We can support your engineering efforts by assisting with your part design for plastic injection molding, by creating the 3D CAD data from your 2D prints or sketches, and reverse engineering of existing parts.?

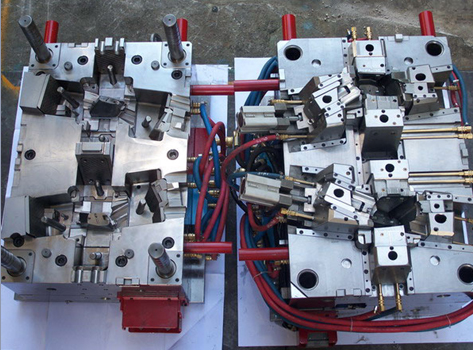

our Senior Tooling Engineer

has experienced in?Plastic Tooling/Die and have in-depth experience in tooling concepts. They will monitor each step of the tooling process and ensure a certain level of quality is delivered.

【Management】

【Management】